Streamline Production. Automate Workflows. Optimize Resources.

BrainPack AI Manufacturing

Revolutionize Your Production Process with AI-Driven Manufacturing

BrainPack AI Manufacturing empowers your production line by automating workflows, predicting maintenance needs, and optimizing resource allocation. Leverage AI to reduce downtime, increase efficiency, and manage your entire manufacturing process seamlessly.

Next-Gen Manufacturing Capabilities

✔ Automated production planning to optimize workflows

✔ Predictive maintenance to reduce equipment downtime

✔ Real-time production tracking for better control

✔ Smart resource allocation to minimize waste

✔ Automated inventory management for seamless supply

Why BrainPack AI Manufacturing?

Maximize efficiency and minimize downtime with AI-driven insights.

BrainPack AI Manufacturing automates production planning, quality control, and maintenance scheduling. Gain full visibility into your manufacturing process and make data-driven decisions that enhance productivity.

Part of the Operations & Logistics Pack

Includes: Manufacturing, Inventory, Purchase, PLM, Quality, Maintenance, Fleet, Planning — everything you need to manage production and supply chains efficiently.

Key Features

BrainPack AI Manufacturing offers robust tools to streamline production, manage resources, and optimize your supply chain. Automate repetitive tasks and gain insights to enhance productivity.

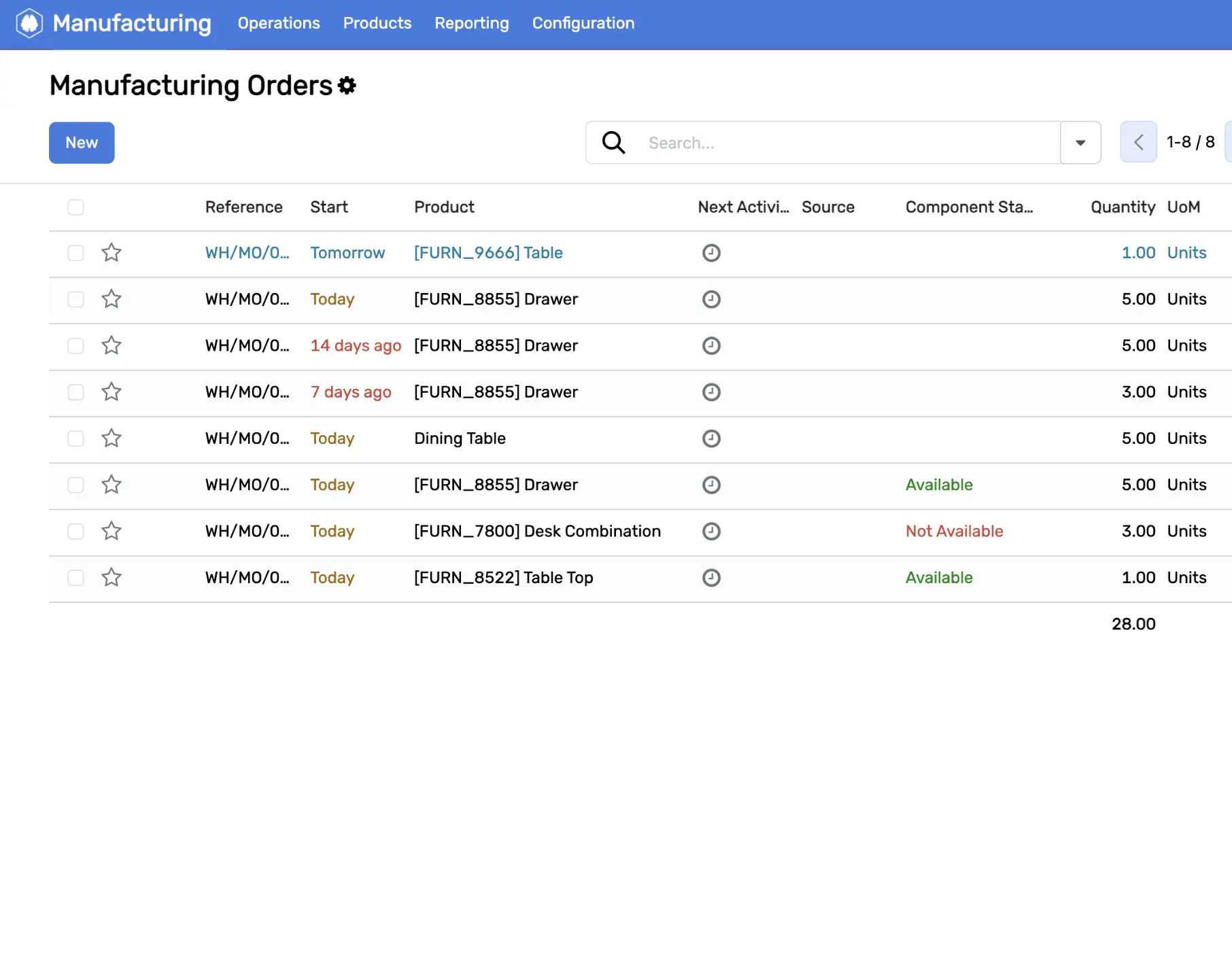

Real-Time Production Tracking

Monitor production stages in real-time. Track machine performance, production rates, and output quality with AI-powered analytics.

Automated Work Order Management

Create, assign, and track work orders automatically. AI prioritizes tasks based on urgency, availability, and resource constraints.

Works With All BrainPack Apps

Integrates seamlessly with Inventory, Purchase, Maintenance, Quality, and more. Maintain a streamlined production line that aligns with your business goals.

Integrated Machine Monitoring

Connect to IoT devices for real-time monitoring of machinery. AI detects anomalies and alerts operators to potential issues.

Quality Assurance Automation

Implement AI-driven quality checks during production. Automatically log defects and track resolutions.

Predictive Maintenance

AI monitors equipment performance and predicts maintenance needs before failures occur. Automate maintenance scheduling to reduce unplanned downtime.

Resource Optimization

Automatically allocate raw materials, labor, and machine time to minimize waste and maximize output. AI suggests adjustments based on historical data.

Smart Production Planning

Automate scheduling and resource allocation based on demand forecasts. AI dynamically adjusts production plans to minimize bottlenecks.

AI Features That Set You Ahead

Downtime Prediction Models

AI forecasts machine failures to schedule maintenance.

Real-Time Performance Metrics

Monitor production rates and identify inefficiencies.

Production Forecasting

AI predicts output based on raw material availability.

Smart Resource Allocation

Automate distribution of labor and materials.

Quality Anomaly Detection

Spot defects early with automated visual inspection.

Automated Compliance Reporting

Generate reports for regulatory compliance effortlessly.

Integrations & Compatibility

- Works with BrainPack: Inventory, Maintenance, Quality, Purchase

- Open API for custom integrations

- Support for IoT device connectivity

- Fully mobile-optimized for factory floor management

Enhance Production with BrainPack AI

Automate planning, optimize resources, and reduce downtime.

BrainPack AI Manufacturing empowers your production line with smart, data-driven decisions.

Frequently asked questions

Yes — AI dynamically schedules production based on demand and resource availability.

Absolutely — AI monitors equipment health and suggests maintenance schedules.

Yes — monitor each stage of production and track output metrics.

Yes — connect machines for real-time performance monitoring and alerts.